How to Save Money on Construction Equipment Without Sacrificing Quality

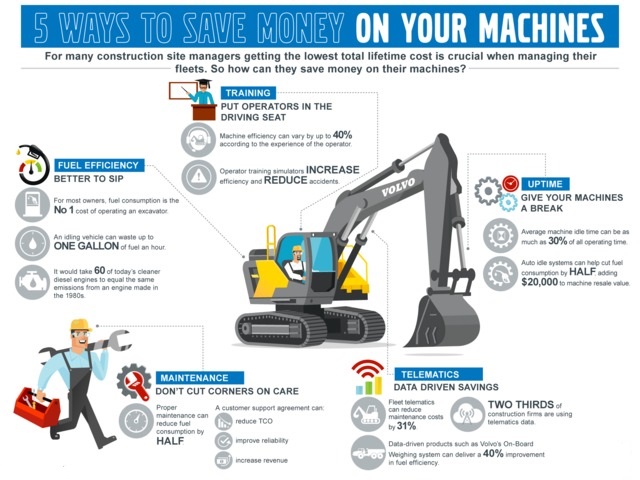

Investing in machinery is a major expense for any business, but it doesn’t have to break the bank. Whether you’re acquiring new equipment or managing the machines you already own, there are several smart ways to lower costs without sacrificing efficiency or performance. Here are five proven strategies to help your business save money on construction equipment over the long term.

1. Invest in Quality Equipment or Buy Refurbished

It might seem counterintuitive, but sometimes spending more upfront can lead to major savings later. High-quality machines are built to last and require fewer repairs, which reduces your total cost of ownership.

According to Take Charge America, reliable equipment helps you avoid frequent replacements and unexpected repair bills.

Alternatively, consider refurbished equipment—a cost-effective option that can save you 30–50% compared to buying new, notes Speed-Tech Equipment.

2. Stick to a Preventative Maintenance Schedule

Don’t wait for machines to fail—schedule preventative maintenance instead. Regular inspections, cleanings, lubrication, and monitoring for wear and tear can drastically extend equipment life and reduce costly downtime.

MacAllister Machinery emphasizes that proactive maintenance prevents major issues before they start.

Plus, the Louisiana Department of Energy reports that well-maintained equipment uses energy more efficiently, leading to lower utility costs.

3. Reduce Energy Consumption

Energy costs can be a hidden expense of operating equipment. Simple steps like turning off idle machines, unplugging unused electronics, and choosing energy-efficient models can cut monthly bills significantly.

The California Public Utilities Commission recommends using features like air-dry settings on dishwashers and unplugging unused equipment.

The U.S. Department of Energy suggests covering pans when cooking or matching burner size to pan size to save energy—practices that can also apply to industrial settings.

4. Manage Parts Strategically

Downtime from waiting on parts can be costly. By maintaining a stock of commonly used components—like belts, hoses, and hydraulic pumps—you reduce delays in getting machines back online.

Yarbrough Industries advises standardizing parts across multiple machines where possible, and buying in bulk to secure discounts.

5. Train Your Team and Partner with Experts

Knowledgeable employees are one of the best tools for saving money. Proper training ensures machines are operated correctly and minor issues are addressed before they become costly problems.

According to Wagner Equipment Company, businesses save significantly when teams are trained to handle basic maintenance. For more technical issues, develop relationships with trusted service professionals who offer fast, cost-effective repairs.

Conclusion: Saving Money on Equipment Starts with Strategy

From buying refurbished machines to improving energy efficiency and training your team, there are plenty of ways to cut costs without compromising on performance. With these strategies, your business can save money on construction equipment while maintaining a competitive edge.